Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Send Inquiry

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:Ningbo,China

Productivity:1000,00/Month

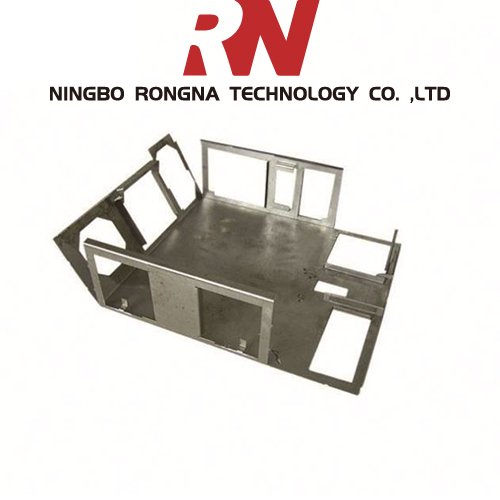

Precision Sheet Metal Stamping Parts Service Sheet Metal parts are Precision Sheet Metal Service products, we can't live anywhere without sheet metal parts. Sheet metal parts are made by filament power winding, laser cutting, heavy processing, metal...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:China,Ningbo

Productivity:10000/Month

Custom Metal Fabrication Galvanized Fabrication The Flange Metal Parts- Sheet Metal Fabrication for embedded parts usually consists of the following steps. 1. Design: The first step in the process is to design the product. It can be designed using...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

High End Technology Sheet Metal Fabrication Service Sheet metal is a comprehensive cold working process of sheet metal (generally less than 6 mm), which specifically includes cutting, punching/cutting/composite, folding, welding, riveting, splicing,...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:Ningbo,China

Productivity:1000,00/Month

Hot Selling Metal Fabrication Product Custom Aluminium In order to meet the requirements of product function and appearance, the design of sheet metal parts should ensure that the stamping process is simple, the stamping die is easy to make, the...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:Ningbo,China

Productivity:1000,00/Month

Precision Sheet Metal Fabrication Sheet metal processing is called sheet metal processing. Specifically, for example, the use of plates to make chimneys, iron drums, fuel tanks and oil cans, ventilation pipes, elbows and heads, round places,...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:Ningbo,China

Productivity:1000,00/Month

Sheet Metal Fabrication Metal plate fabrication is the process of converting metal plates into various shapes and sizes. It involves using various machines and tools to cut, bend, and weld metal plates into desired shapes. The most common metal...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:Ningbo,China

Productivity:1000,00/Month

Precision Sheet Metal Components In 3D software, SolidWorks, UG, Pro/E, SolidEdge, TopSolid, etc. all have sheet metal components, mainly through the editing of 3D graphics to obtain the data required for sheet metal brackets processing (such as...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:Ningbo,China

Productivity:1000,00/Month

CNC Sheet Metal Fabrication CNC sheet metal processing is simple to understand, is the use of CNC technology in sheet metal processing, in order to better processing operation, better processing effect. Generally speaking, there are usually the...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:China,Ningbo

Productivity:10000/Month

Custom Made Steel Aluminum Casting Parts Rapid Prototype Mental Fabrication Service is an essential “artifact” in many industries nowadays. It is no longer limited to the hardware industry. In recent years,Rapid Prototype Mental Fabrication Service...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:China,Ningbo

Productivity:10000/Month

Flange Sheet Metal Fabrication Parts Service Flange Sheet Metal Fabrication Parts Service are components used in a variety of industries including automotive, aerospace, construction and manufacturing. These pieces are made of sheet metal and are...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:China,Ningbo

Productivity:10000/Month

Shovel Metal Sheet Fabrication Parts Custom Industrial Sheet Metal Fabrication is the process of cutting, bending, and shaping sheet metal to create a finished product. This process using various tools and techniques to transform metal flat sheets...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:China,Ningbo

Productivity:10000/Month

Good Sale Industrial Sheet Metal Fabrication In Low Cost Sheet Metal Fabrication Service processing, various methods are used to apply force to the sheet metal to form the target shape. The principle is related to the characteristics of the metal...

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:China,Ningbo

Productivity:10000/Month

Custom Sheet Metal Folding Fabrication Services Check the rail grease charge every week. If necessary, the laser cut pattern moistens the equipment rails to maintain the moisturization of the exercise components and increase the life of the rails....

USD 0.1 ~ 80

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Express,Air

Packaging:wooden box / carton / tray / Custom way

Supply Ability:1000,00/Month

Place of Origin:China,Ningbo

Productivity:10000/Month

Custom Precision Sheet Metal Fabrication Service Custom Sheet Metal Fabrication Service can create metal parts and components by cutting, bending, and shaping sheet metal. This service is used in a variety of industries, including automotive,...

Processing steps For Sheet Metal Parts - Custom Sheet Metal Fabrication Service Company

1. Design and draw the part drawing of its sheet metal parts, also known as three views. Its function is to express the structure of its sheet metal parts by means of drawings.

2. Draw an unfolded drawing. That is, unfold a part with a complicated structure into a flat piece.

3. Unloading. There are many ways to unload, mainly the following methods:

a. Shearing machine cuts the material. It uses the shearing machine to cut out the length and width dimensions of the expanded drawing. If there are punching and corner cutting, then the punching machine is combined with the die to punch and corner to form.

b. Punch blanking. It is the use of a punch to punch the structure of the flat part after the parts are unfolded on the plate in one or more steps. Its advantages are short labor hours, high efficiency, and can reduce processing costs. It is often used in mass production.

c. NC CNC blanking. When NC blanking, you must first write a Cnc Machining program. That is, use the programming software to write the drawn expanded diagram into a program that can be recognized by the NC CNC machining machine. Let it follow these programs step by step on a piece of iron plate On the top,punch out the structural shape of its flat parts.

d. Laser cutting is the use of laser cutting to cut the structure and shape of the flat piece on an iron plate.

4. Flanging and tapping. Flanging is also called hole extraction, which is to draw a slightly larger hole on a smaller base hole, and then tap the hole. This can increase its strength and avoid slippage. Generally used for sheet metal processing with relatively thin plate thickness. When the plate thickness is large, such as the plate thickness of 2.0, 2.5, etc., we can tap directly without flanging.

5. Punch processing. Generally, punch processing includes punching and cutting corners, punching blanking, punching convex hull, punching and tearing, punching and other processing methods to achieve processing purposes. Its processing requires corresponding molds to complete the operation. There are convex molds for punching convex hulls, and tearing forming molds for punching and tearing.

6. Pressure riveting. As far as our factory is concerned, pressure riveting studs, pressure riveting nuts, pressure riveting screws, etc. are often used. The pressure riveting method is generally completed by a punch or hydraulic pressure riveting machine. Riveted to the sheet metal part.

7. Bending. Bending is to fold 2D flat parts into 3D parts. Its processing requires a folding bed and corresponding bending molds to complete the operation. It also has a certain bending sequence, and the principle is to make the next cut The first fold that does not cause interference will produce the interference back fold.

8. Welding. Welding is the group welding of multiple parts together to achieve the purpose of processing or the edge welding of a single part to increase its strength. The processing parties generally include the following: CO2 gas shielded welding, argon arc welding, Spot welding, robot welding, etc. The selection of these welding methods is based on actual requirements and materials. Generally speaking, CO2 gas shielded welding is used for iron plate welding; argon arc welding is used for aluminum plate welding; robot welding is mainly in-material It is used when the parts are large and the welding seam is long. Such as cabinet welding, robot welding can be used, which can save a lot of tasks and improve work efficiency and welding quality.

9. Surface treatment. Surface treatment generally includes phosphating film, electroplating colorful zinc, chromate, baking varnish, oxidation, etc. Phosphating film is generally used for cold-rolled plates and electrolytic plates, and its function is mainly to plate on the surface of the material. A protective film is applied to prevent oxidation; the second is to enhance the adhesion of its baking paint. Electroplated multicolored zinc is generally treated with cold-rolled plate surface treatment; chromate and oxidation are generally used for surface treatment of aluminum plates and aluminum profiles; its specific surface The choice of treatment method is based on the customer's requirements.

10. Assembly. The so-called assembly is to group multiple parts or components together in a certain way to make them into a complete material. One thing that needs to be paid attention to is the protection of the materials, and no scratches. Assembly is the last step in the completion of a material. If the material cannot be used due to scratches, it needs to be reworked and reworked, which will waste a lot of processing man-hours and increase The cost of the item. So pay special attention to the protection of the item.

Address: No.69 ZiLin Road,YuYao, Ningbo, Zhejiang China

Tel: +86-0574-62520922

Website: https://www.service-machining.com

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.